Call 01480 8-9-10-11 | Email Us | Mon-Fri 9am–5pm | Customer Login | Vacancies | Videos

Call 01480 8-9-10-11 | Email Us | Mon-Fri 9am–5pm | Customer Login | Vacancies | Videos

ISN Garage Assist Blog

The Wheel Alignment Blog | Watch the Steering!

Following a standard service and adjustment, there is nothing quite as frustrating as putting your alignment system away, only to find customers complaining that the steering wheel isn't straight when the vehicle is driving in a straight line.

This month we are going to look at a very common issue. Its one that regularly turns out to be the cause of misalignment yet is mostly nothing to do with your alignment system at all. However, it is all to do with how you use it. I'm going to tackle the all too common issues with alignment relating to the steering wheel straightness.

Following these steps and tips should help ensure the steering wheel and alignment match up every time:

- Firstly, ensure your machine is correctly calibrated

- Ensure your turn plates are in good condition

- Complete your vehicle pre-checks, I.E Tyre pressures, Tread wear, joint play etc.

- Check to see if you have clean lenses (CCD) or targets (3D)

- Ensure the clamps are fitted evenly around the rim (Ensure run out is done if using uncalibrated clamps I.E. 4 point)

- Always use 4 wheel alignment, not 2! (2 wheel alignment is only suitable for old vehicles where the rear wheels are hidden under arches.)

- You should not be sitting in the car when you put on the steering wheel clamp on. Instead, lean into the vehicle to avoid any change to the bump steer in the car.

- Remember: clamp your steering wheel straight as that is where it will be when driving straight ahead. (Many customers clamp the steering wheel near the end of a castor swing believing the computer is asking you to clamp when straightening the front wheels.)

- Continue with your alignment, bearing the below potential issues in mind.

Take a look at the Balco i-Lign 8 CCD Wheel Aligner, aTablet Operated Wheel Alignment System.

Post Alignment Check

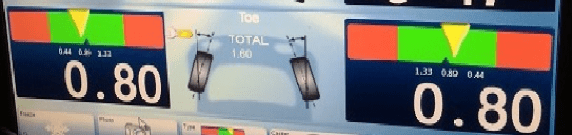

At the end of the alignment process, and just before you start to remove the heads/clamps, on select systems you are able to click back to the front toe screen in the alignment program. If you remove the clamp and wiggle the steering wheel from side to side, the numbers on the screen should change accordingly. Now try and equal the toe numbers either side. Stand back – the steering wheel should be straight. If not, re-centre the wheel and re-adjust the toe.

Steering Wheel Alignment Issues to look out for:

- When undoing seized or tight lock nuts, the extra force used could move the steering wheel around. It is only the steering wheel clamp that holds the front wheels straight so be careful!

- I've found a lot of customers will heat up locked nuts or track rod ends to get them moving. As we know though, heat expands the metal and this can mean your system will give the incorrect readings. You can solve this by first getting the nut to move freely, then cooling it down with a cloth soaked in cold water. Now make the adjustment. You should be replacing the track rod ends as new MOT laws now forbid the heating of these components

Crabbing

Crabbing is a common term used by mechanics and customers alike, but it should really be referred to as a vehicles thrust line. This is the direction that the rear road wheels/ axle are pointing.

On more basic alignment machines, such as laser or even some computer systems, it is important to check the rear alignment as well. Failing to ensure the rear wheels are in-line with the front may cause the vehicle to "crab". This will mean you'll never get the steering wheel straight. The driver of this car would be turning their wheel to the left just to drive straight!

It is important to understand that the rear wheels are dictating the direction of the car and the front wheels are only compensating to keep the vehicle straight or steer. This is why it is important to find the thrust line and compensate for it when using lasers.Note: Most modern computers will compensate for this issue.

When you subscribe to the blog, we will send you an e-mail when there are new updates on the site so you wouldn't miss them.